Louver impregnation process

Release time:

Aug 08,2024

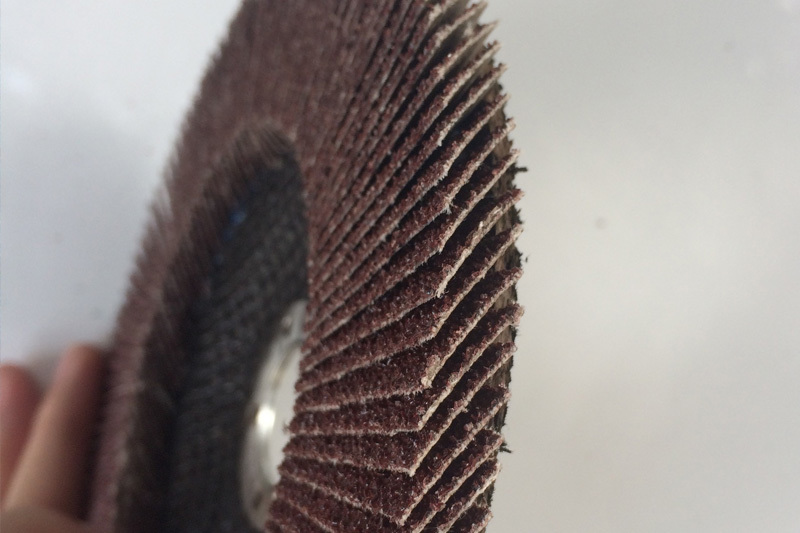

Impellers, polishing sand and other abrasive tools are often treated by dipping process.

In order to obtain good use effect, the impeller, polishing sand and other abrasive tools are often treated with impregnation process. Now, the impregnation process is mainly divided into two kinds of traditional process and modern process. In these two processes, the modern process has obvious advantages. The specific contents are as follows:

The impregnation treatment of the traditional impeller is a process of grinding wheel treated with various impregnants based on stearin and sulfur, which can enhance the grinding performance of the grinding tool. However, this process often reduces the use effect of the grinding wheel. The main reason is that these components do not form a homogeneous melt, with the hard fat distributed above and the sulfur distributed below. The modern impregnation treatment process is developed on the basis of the traditional treatment process. The modern impregnation process is to first heat the grinding wheel to 140-150 ℃, then put it into the heated impregnation solution and rotate it for 4 minutes with pulses. In this way, all the components of the impregnating agent can be impregnated uniformly in the grinding wheel. The grinding wheel is lifted out of the melt and rotated, relying on the rotation to cause the grinding wheel to throw away excess impregnating agent. The grinding wheel throws off the excess impregnating agent according to this specification, and the diamond will not form a tumor when dressing, and the surface will not be greasy when grinding, and will not be produced on the surface to be ground.

From the above introduction, we can understand the many advantages that can be obtained by the modern impregnation process of the impeller. Then we will not hesitate to directly choose the modern impregnation process when dealing with the impeller. This is the experience summed up by many users.

The impeller can make the cutting angle reach when polishing the processed parts, and the base material of the sanding wheel is consumed synchronously with the sanding, which obviously improves the overall and grinding efficiency of the flat sanding wheel and prolongs the service life of the sanding wheel. Then the reasons for the sliding of the hot plate of the impeller are:

1. is the slippage caused by excessive force used during polishing. Because your strength is different, the polishing effect is also different, so the effect is also different during use, so the polishing should be properly controlled. Strength.

The 2. is that the chuck of the grinder is not locked or the impeller is unqualified and cannot be clamped, so the quality of the impeller or the mechanical device should be checked before use, and the impeller should be replaced or re-locked.

Through the above introduction, we have learned the reason why the impeller slips when grinding the hot plate, so we should use it well when we use it. When we encounter the situation that the impeller slips when grinding the hot plate, we can solve it according to the above reasons.

We intend to divide the inspection procedures for 100 impellers into three parts. First, let's talk about what is slitting and slicing inspection:

1.1. Slitting inspection: The abrasive cloth strips separated by the slitting machine shall be uniform in width and shall be as small as possible to reduce the generation of burrs. The divided strips shall be coiled neatly and placed according to categories.

1.2. Slice inspection: The slicer should work under the condition that the emery cloth can be cut off, and the position of the movable knife and the fixed white steel knife should be changed frequently (two rolls of emery cloth are temporarily cut and changed and adjusted once, depending on the specific situation) to make it have a better cutting edge, increase its cutting performance, keep the appearance of the cut pieces neat, and avoid burrs as much as possible.

Key words:

Learn more about industry dynamics

Specializing In The Production Of Various Abrasive Products

Main Products

Specializing in the production of flat abrasive cloth wheel, Korean flower-shaped impeller, abrasive belt, fiber reinforced resin cutting wheel, fiber reinforced resin grinding wheel and other series of abrasive products, is a research and development, production, sales as one of the enterprises.

Contact Us

Phone:+8618631680262Wang Sai

E-mail:Markdouya@jrktools.com

Add: Manzhongliang Industrial Development Zone, Shu Town, Hejian City, Cangzhou City, Hebei Province

Quality of service to win customer satisfaction

Scan code to browse the official website

Learn more about abrasive products at any time